Hi Eline. We encourage

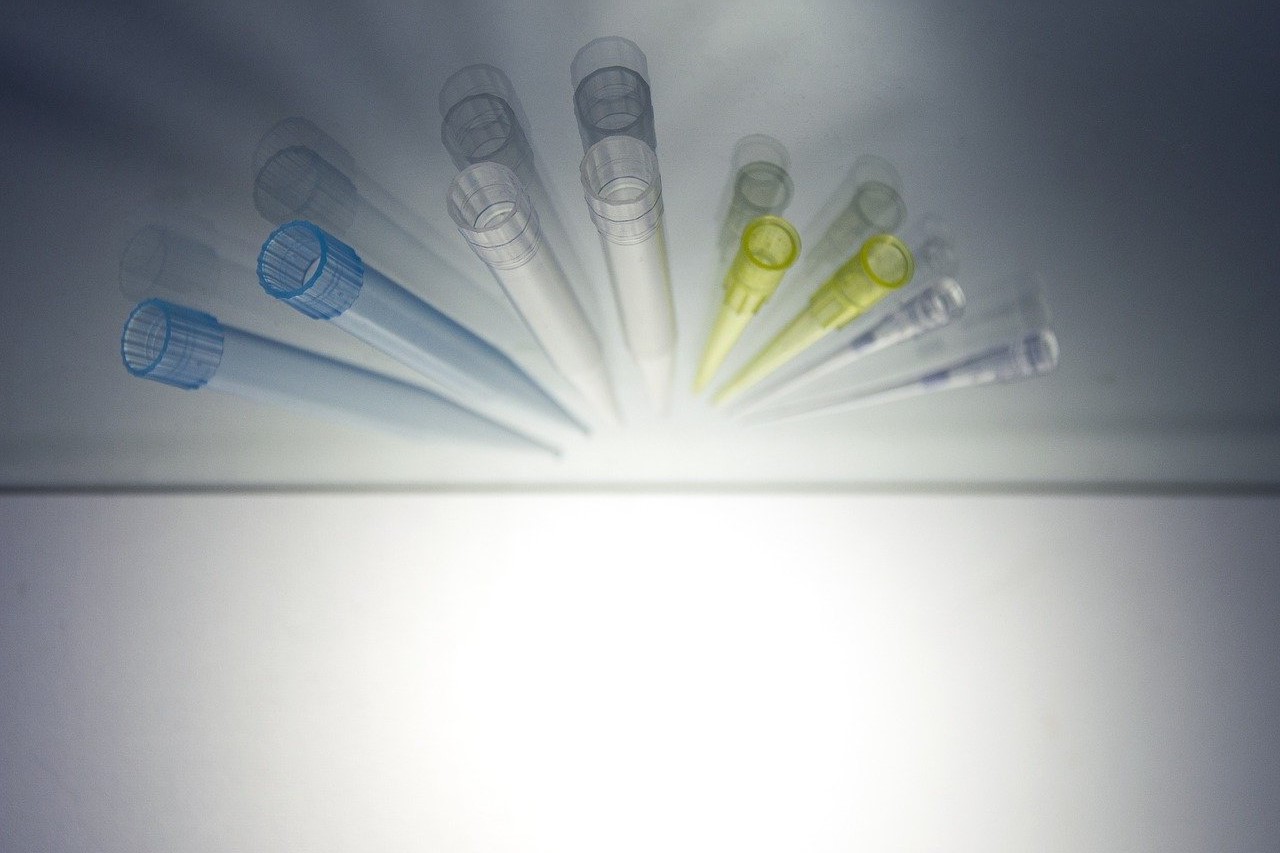

looking at waste using the well-known mantra: Reduce, Reuse, Recycle.

The first steps

should always be to look into reducing and reusing. This would be thinking

about how you run your experiments. Is there a way to optimize so that you use

fewer pipette tips?

Good planning can

mean you prepare your samples together and only use one pipette tip for each

chemical, or if you have variable amounts, to pipette twice with a smaller tip,

rather than switching to a bigger pipette tip for that one single sample. Can

you reduce the size of your experiments, so that you can use smaller pipette tips? For

the appropriate experiment/chemical, you can also label the used pipette tip

and reuse it multiple times throughout the day.

Choosing tips made from recycled plastics or switching to glass may also be options. And there are pipette tip washers on the market for those who want to go the extra mile.

Plastic pipette tips can

absolutely be recycled, but not each waste hauler has the facilities or the confidence to do so.

You need to go and discuss with your particular waste hauler and your HS&E

department. Different suppliers make their tips out of different plastics, so

maybe by changing pipette tip brands, you can find something your waste hauler can

recycle. The trickiest part tends to be convincing your waste hauler that your tips are not contaminated and have not interacted with any chemicals that will degrade the plastic.

Although it is

currently in its infancy, we have examples of successful pipette tip recycling.

Usually, it means separating your tips into hazardous/non-hazardous,

decontaminating them and then depositing them in a puncture proof recycling

container. However, do not do this without the written approval from your waste

hauler. If your waste hauler has not approved and they see pipette tips in the

recycling bag, they will just throw away/incinerate the entire lot because they

aren't sure. It takes a bit of leg work to get a tip recycling program started,

but it is completely possible.

Then of course, we also suggest some peripheral

ways to save. Beyond the actual tips themselves, reduce the amount of waste

associated with pipette tips by reloading your own tips - either from a bag of

tips, or an autoreload system. Pipette tip boxes are great for storing small

things in the lab and there are many good pipette tip box recycling schemes (and

for this you don't necessarily need to go through your waste hauler). Then

there are lots more tertiary reductions, such as combining orders with other

labs to reduce the amount of packing waste and delivery carbon footprint.